Améliorez votre entretien d’embrayage DSG - DSG DQ250

SKU: 901-0737

- Prix habituel

- €1.068,20 EUR

- Prix soldé

- €1.068,20 EUR

- Prix habituel

-

Envoyez-nous votre embrayage et nous le transformerons pour encaisser ce surplus de couple comme un champion. Profitez de passages de rapports ultra-rapides et de performances améliorées qui vous laisseront sans voix. Là où la précision rencontre la puissance.

*Benefits & Advantages

* Haute capacité de maintien du couple

*Fast and consistent engagement

*Exceptional heat resistance

* Construction renforcée RTMG Performance

*Improved pedal feel

* Durée de vie prolongée

* Conçu par l’équipe 4 cylindres la plus rapide (7 s) avec DQ250

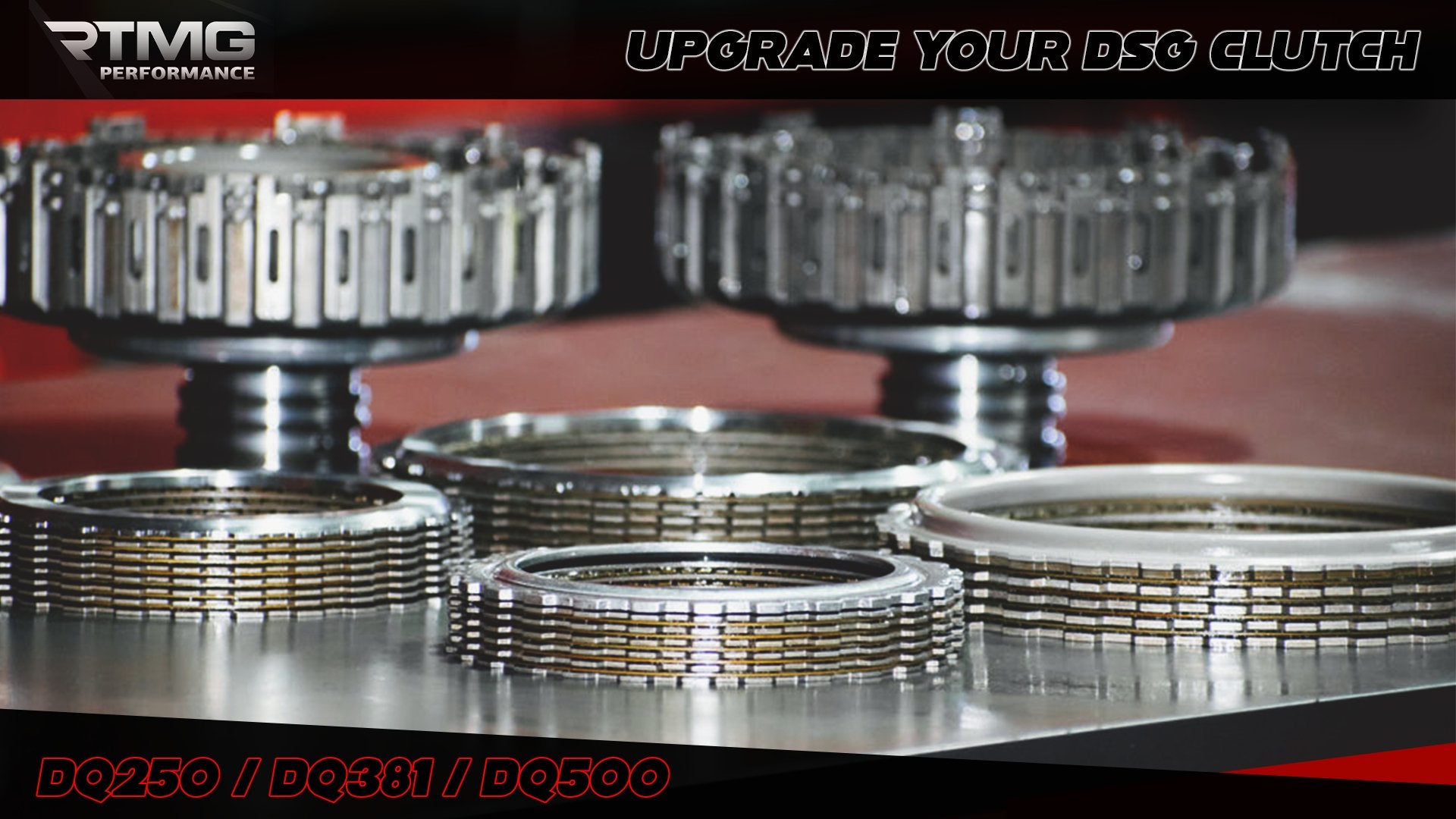

Présentation des embrayages multidisques humides

Notre équipe chez RTMG Performance, après un long travail de recherche et développement dans les conditions les plus exigeantes des courses de dragster, est parvenue à résoudre tous les problèmes de développement des embrayages de boîte 02E DQ250. Au départ, nous avons testé tous les matériaux de friction, dont la plupart présentaient un coefficient de friction inférieur à celui de l’embrayage d’origine. Certains de ces matériaux avaient non seulement un coefficient de friction plus faible, mais produisaient également des résidus qui obstruaient, voire endommageaient parfois les solénoïdes.

Après deux ans de tests continus sur la piste de Santa Pod en Angleterre, nous avons acquis des informations inestimables pour réussir l’un des défis les plus difficiles : établir le record d’Europe sur 0-400 mètres (quart de mile) avec un temps de 7,8 secondes et une vitesse de sortie de 300 km/h avec un moteur de 2,0 L.

Comment avons-nous développé l’embrayage ?

L’embrayage peinait à encaisser l’incroyable launch control de notre moteur, qui délivre près de 1 400 chevaux dans une Golf 6 2.0L TSI. Après environ chaque 5 passages, nous démontions l’embrayage pour inspecter l’usure. Nous avons testé de nombreux matériaux de friction jusqu’à finalement sélectionner le matériau actuel.

Le point le plus critique concernait toutefois les plateaux métalliques, qui se déformaient lorsque la voiture devait parcourir les 18 premiers mètres le plus rapidement possible à l’arrêt, tout en évitant la surchauffe de l’embrayage afin de prévenir tout patinage à haute vitesse et sous forte pression de suralimentation. Cela a conduit à de nombreux essais avec différents matériaux jusqu’à ce que nous trouvions un acier présentant un coefficient de friction élevé mais également une grande résistance aux hautes températures, sa structure cristalline l’empêchant de se déformer aussi facilement que d’autres matériaux, y compris les pièces d’origine. Le matériau que nous utilisons est traité thermiquement par revenu, ce qui soulage les contraintes et empêche la déformation sous les températures extrêmement élevées générées lors du fonctionnement de l’embrayage au départ arrêté.

Le résultat n’a pas été seulement le temps réalisé, mais aussi le record de piste et le record d’Europe pour les voitures à traction avant : 1,3006 seconde sur 0–18 mètres.

Quelques mots sur la transmission de puissance.

Le couple est généré par le moteur et transmis à travers les éléments de la chaîne cinématique : volant moteur, embrayage, boîte de vitesses, différentiel, arbres de transmission, puis finalement aux roues. Quel est le rôle de l’embrayage ici ? L’embrayage doit transmettre les tours et le couple du moteur à la boîte de vitesses lors du départ, lorsque le moteur passe de 5 000 tr/min en launch control à l’entraînement de la boîte à 0 tr/min. Il y a des éléments fixes et des éléments tournants. Dans l’embrayage, les éléments fixes sont les disques organiques montés avec les mécanismes sur l’embrayage et reliés à la boîte de vitesses, tandis que les éléments tournants comprennent le moteur, le volant moteur, le panier d’embrayage et les plateaux métalliques, qui y sont intégrés et flottants.

Lorsque le conducteur initie le départ en relâchant le frein tout en gardant l’accélérateur à fond, l’unité de commande de la boîte de vitesses comprime un piston qui pousse les plateaux métalliques et serre les disques organiques. Le frottement généré entre ces composants amène les disques fixes à tourner à la même vitesse que les disques mobiles.

Pour y parvenir, plusieurs facteurs entrent en jeu, tels que le coefficient de friction, la surface de contact, le rayon auquel se situent les matériaux de friction par rapport à l’axe, la vitesse de refroidissement et la dissipation thermique, qui est une convection forcée. Nous avons amélioré nos résultats en :

a) Augmentant la surface de friction.

b) Augmentant le coefficient de friction.

Tout cela a été obtenu en augmentant le nombre de disques métalliques et organiques et en installant une bague en bronze au lieu d’une bague en plastique pour la configuration stage 3, afin d’éviter qu’elle ne fonde à haute température.

Bienvenue dans notre équipe, bienvenue dans la nouvelle génération d’optimisation des performances !