Mejora tu servicio de embrague DSG - DSG DQ250

SKU: 901-0737

- Precio habitual

- €1.068,20 EUR

- Precio de oferta

- €1.068,20 EUR

- Precio habitual

-

Envíanos tu embrague y lo transformaremos para que soporte ese par extra como un campeón. Disfruta de cambios ultrarrápidos y un rendimiento mejorado que te dejará sin palabras. Donde la precisión se encuentra con la potencia.

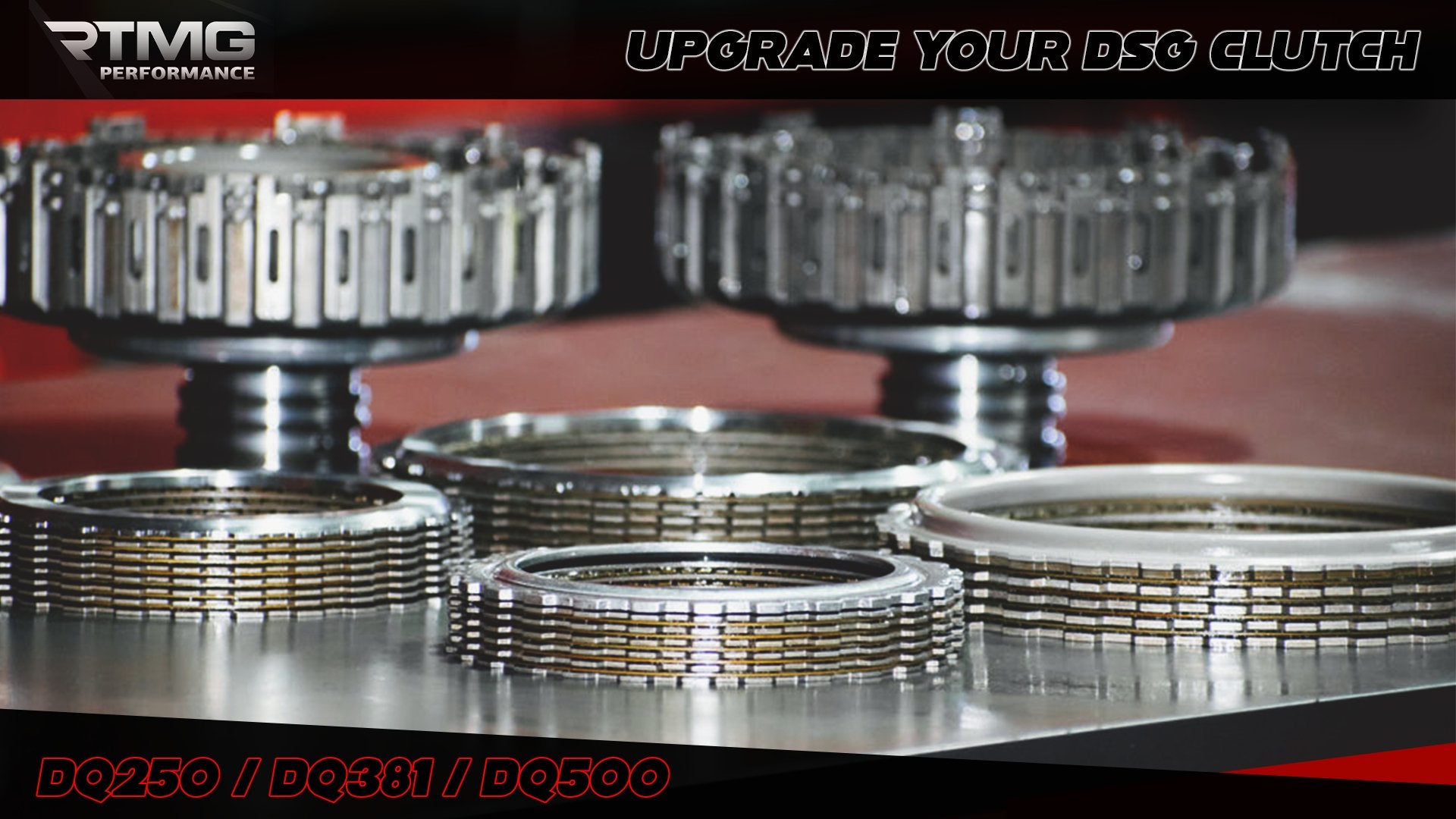

Presentation of Wet Multi-Disc Clutches

Our team at RTMG Performance, after extensive research and development under the most challenging conditions of dragster racing, managed to solve all the development issues of the 02E DQ250 gearbox clutches. Initially, we tested all friction materials, most of which had a lower friction coefficient compared to the factory clutch. Some of these materials not only had a lower friction coefficient but also produced residues, which clogged or sometimes even damaged the solenoids.

Tras dos años de pruebas continuas en el circuito de Santa Pod en Inglaterra, obtuvimos información inestimable para lograr una de las hazañas más difíciles: establecer el récord europeo en los 0-400 metros (o cuarto de milla) con un tiempo de 7,8 segundos y una velocidad de salida de 300 km/h utilizando un motor de 2,0 L.

How did we develop the clutch?

The clutch struggled with the incredible launch control of our engine, which delivers close to 1,400 horsepower in a 2.0L TSI Golf 6. After approximately every 5 passes, we would remove the clutch and inspect the wear. We tested numerous friction materials until we finally selected the current material.

The most critical point, however, was in the metal plates, which deformed as the car had to cover the first 18 meters as quickly as possible from a standstill, while at the same time ensuring the clutch did not overheat to avoid slipping at high speeds and under high turbo pressures. This led to extensive testing with many materials until we found a steel that had a high friction coefficient but was also highly resistant to high temperatures, as its crystalline structure prevented it from deforming as easily as other materials, including the factory parts. The material we use is thermally treated with tempering, which relieves stress and prevents deformation under the extremely high temperatures generated during the clutch's operation during the launch.

El resultado no fue solo el tiempo que logramos, sino también el récord del circuito y de Europa para coches de tracción delantera: 1,3006 segundos en 0-18 metros.

A few words about power transmission.

El par se genera en el motor y se transmite a través de los componentes de la cadena cinemática: volante motor, embrague, caja de cambios, diferencial, palieres y, finalmente, a las ruedas. ¿Cuál es la función del embrague aquí? El embrague debe transferir las revoluciones y el par del motor a la caja de cambios durante la salida, donde el motor pasa de 5.000 RPM en launch control a hacer girar la caja de cambios desde 0 RPM. Hay componentes fijos y giratorios. En el embrague, los componentes fijos son los discos orgánicos montados con mecanismos en el embrague y conectados a la caja de cambios, mientras que los componentes giratorios incluyen el motor, el volante motor, la campana del embrague y los platos metálicos, que van integrados y flotando sobre él.

As the driver initiates the launch by releasing the brake while flooring the throttle, the gearbox control unit compresses a piston that pushes the metal plates, squeezing the organic discs. The friction generated between these components causes the fixed discs to rotate at the same speed as the rotating ones.

To achieve this, several factors come into play, such as the friction coefficient, the surface area, the radius at which the friction materials are located relative to the axis, the cooling rate, and the heat dissipation, which is forced convection. We improved our results by:

a) Increasing the friction surface area.

b) Increasing the friction coefficient.

All of this was achieved by increasing the number of metal and organic discs and installing a bronze bushing instead of a plastic one for the stage 3 setup, to prevent it from melting at high temperatures.

Welcome to our team, welcome to the next generation of performance enhancement!