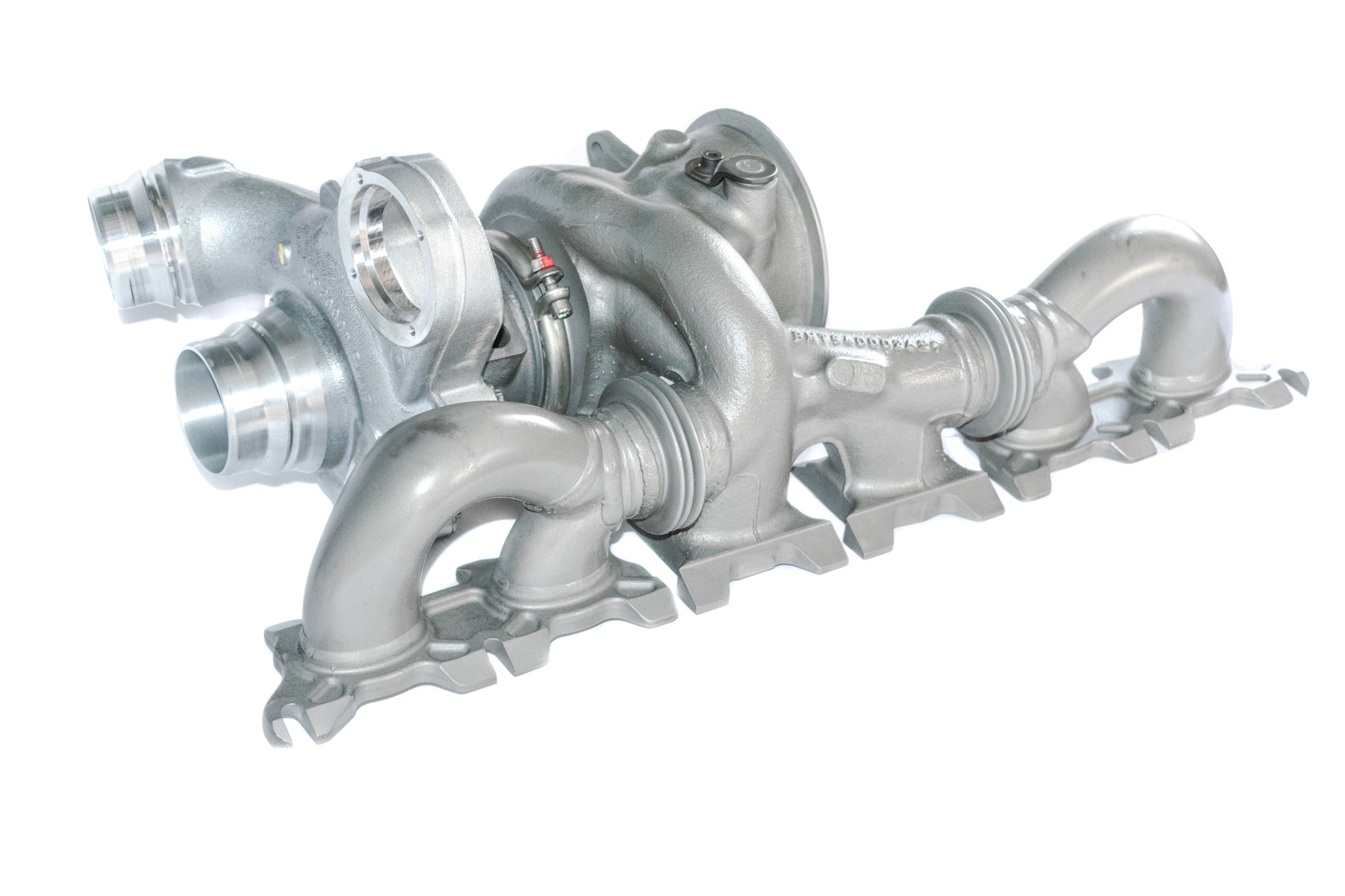

Hybrid Turbocharger 600RS for BMW B58 M240i / M140i / 340i / 440i / 540i / 740i

SKU: 901-0516

- Regular price

- €1.297,10 EUR

- Sale price

- €1.297,10 EUR

- Regular price

-

-

Fast spool

-

Large, CNC-machined, billet aluminum compressor wheel

-

Compressor housing CNC-machining according to the compressor wheel geometry

-

Large Inconel turbine wheel

-

Turbine housing CNC-machining according to the turbine wheel geometry

-

Brand-new bearings and thrust washer

-

RTMG Performance Quality

-

Airflow for up to 600 HP

-

VSR Machine Balanced

- Made in Greece

Engine Codes: B58B30

OEM Part Number: 11652397070

Reference No: 11658637041, 7643147

Vehicles:

- BMW M140 i (F20/F21) 340HP

- BMW M240 i (F22/F23) 340HP

- BMW 340i (F30/F31) 326HP

- BMW 340i GT (F34) 326HP

- BMW 440 i (F32/F33) 326HP

- BMW 440 i GT (F36) 326HP

- BMW 540 i (G30) 340HP

- BMW 740 i (G11/G12) 326HP

Presentation of the Upgraded Turbocharger by RTMG PERFORMANCE

What is a hybrid turbocharger, and how did it become popular?

The hybrid turbocharger became known many years ago when turbocharger repair shops, in order to fix damaged turbos, started using larger compressor wheels and shafts to cover up the damage caused by wheel-to-housing contact. That's how it all began. After a proper repair, many workshops noticed an increase in power, while some experienced a decrease due to poor workmanship or lack of knowledge.

What is a hybrid turbocharger?

It's essentially the same factory turbocharger but with larger compressor and turbine wheels, allowing for greater airflow. More airflow, combined with more fuel, equals more power. The greatest benefit of a well-built hybrid turbocharger is that it doesn't require additional modifications for a larger turbocharger, such as custom manifolds, oil lines, water pipes, air pipes, or exhaust system modifications. These are huge benefits that make the hybrid turbocharger an ideal upgrade when done by professionals with the right CNC machines, reinforced bearings, dynamic balancing with a VSr machine (which balances dynamically to 0.01 g), and performance testing before and after. It is the best value-for-money improvement.

Our Expertise

Our team has a dedicated group of engineers with 15 years of experience in turbocharger repair and upgrades. We own brand-new CNC machines, use advanced CAD-CAM design software for simulating forces, and design high-performance components such as bearings. We also have the latest generation 2024 precision balancing equipment, which measures and tests the performance of the turbo before and after the upgrade in cubic feet per minute (CFM). This is very important because a wrong choice of wheel size that doesn't match the housing can disrupt the energy balance, performance, and spool time of the turbocharger.

Why Choose Our Hybrid Turbochargers?

One of the most important aspects of our services is the perfect fit we achieve with our CNC machines between the turbine and the housing, as our machining precision reaches 0.001 mm. This is crucial, as we follow ISO 9001-2018 standards, which ensures repeatability in every product we manufacture. Another advantage of our hybrid turbochargers is the low-speed balancing done before the VSr balancing, which measures up to 300,000 RPM. During this process, we test the components' behavior under near-real conditions, checking for oil leaks and other issues.

All these steps are included in every RTMG PERFORMANCE turbocharger, and we provide documented results. This, combined with our passion for improvement, has earned us many records and a legacy of satisfied customers worldwide. We never stop researching and developing, as this continuous improvement process allows us to push the boundaries of automotive performance.

Attention: Factors for the Proper Operation of the Turbo

a) This turbo requires a larger cold air intake to operate efficiently.

b) An intercooler capable of handling higher airflow than the turbo's output is necessary.

c) Oil pressure must be maintained at 5 bar.

d) Proper ECU tuning is critical for performance and reliability. Correct tuning prevents the throttle valve from closing, ensuring smooth operation.

e) The catalytic converter must support more horsepower than the turbo produces. Typically, a metallic catalytic converter with 100 cells is recommended. The exhaust system specification is optional but should match the turbo's capacity.

f) The quality and condition of the oil must meet high-performance standards.

g) It is essential to regularly check the air pressure system, maintaining at least 2 bar, to avoid turbo overspeed.

h) A mechanical blow-off valve is recommended, as factory-installed valves may fail to close properly, leading to turbo overspeed.